08/10/2021

Cranes and telehandlers are essential machines on New South Wales construction sites, but they are also big, heavy, and carry big and heavy things. Knowing this, mitigating the risks associated with operating a crane is essential to keeping workers and the general public safe.

Crane hazards can be applied to machines using crane attachments. Hi-Range Crane Forks provide telehandlers with crane attachments available here.

How do crane-related injuries happen?

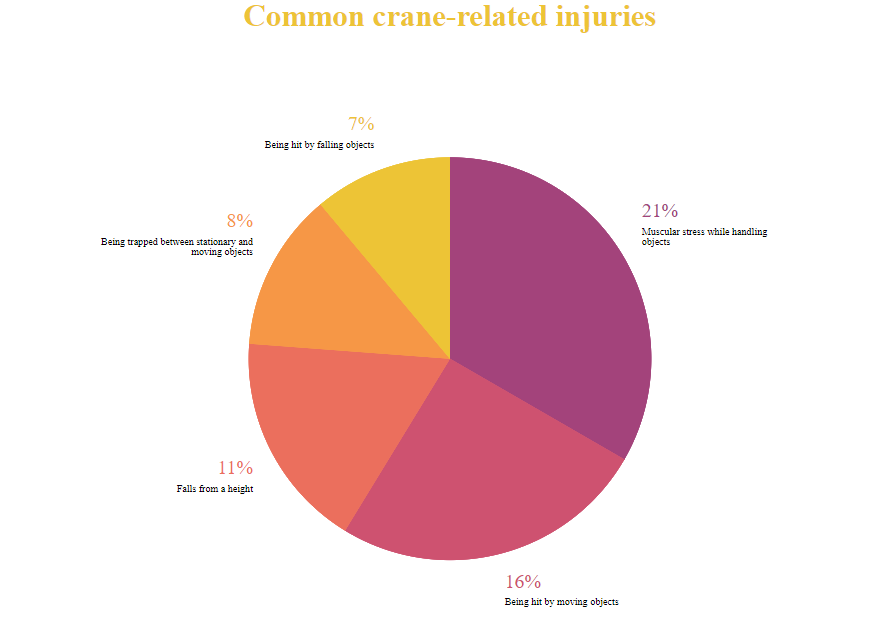

The first step of preventing crane hazards is identifying them. Safe Work Australia estimates that between 2003 and 2015, 47 workers were killed in crane-related accidents, and 240 crane-related injury claims are reported per year on average. Knowing why can help to keep from repeating them.

Data like this can help to identify ways that construction companies can prevent crane hazards. For example, the most common crane-related injury is muscular stress while handling objects - meaning employee education on how to lift heavy objects and knowing your limits on how heavy an object you can lift would reduce this crane-related hazard. Improving traffic management on site could prevent workers being hit by moving objects; improving the safety of tower cranes and man boxes would prevent falls from a height; and centreing loads correctly would prevent workers from being hit by falling objects.

But how do you implement this information?

Choosing a machine

Every machine is built differently, and in the case of machine hire, chances are that they have been used before. To ensure you hire a crane built for your project, check its specifications. Can it lift the loads you will require it to lift? Can it fit into the spaces you require it to fit? Can it manoeuvre around power lines and other obstacles on site? If the answer to any of these questions is “no”, then the machine is not safe to operate on your project.

Most importantly, ensure that you hire a machine from a reputable machine hire company. The machine hire company must be able to prove that the machine for hire is up to date on services, maintenance, and repairs, that the machine is not damaged, and that it is right for the job. Poorly serviced and maintained cranes and telehandlers can turn out weaker than specified, making it difficult for an operator to know if they are overloading the crane or telehandler or centering a load correctly, which can cause loads to fall onto the site below.

Reputable machine hire companies like Hi-Range Crane Forks can provide a consultation service to advise you on which machine to hire on your project, and always provide hirers with well-maintained machines.

Wet hiring a machine

In our blog “4 reasons why a professional should handle your crane”, we talked about how even experienced operators can be vulnerable to breaching work health and safety requirements when operating a machine they have never operated before. When hiring a machine, Hi-Range Crane Forks recommends wet hire, as a professional operator working within the hire company will have experience on the machine you hire. Hi-Range Crane Forks’ operators are licenced and trained to adhere to all occupational health and safety measures on our cranes.

Wet hiring also ensures a greater level of consultation between your construction company and the hire company. With the operator as a liaison on the ground, construction companies have greater access to work health and safety advice specific to the crane. Professional operators with experience on the hired machine can more easily note changes to a crane or telehandler’s load bearing capabilities or any damage it may have sustained. An extra pair of eyes to identify a problem can help to prevent it.

Creating an emergency plan

Emergency plans establish organised and clear prevention methods for an emergency, and organised and clear emergency responses. This means all staff know their part in preventing crane hazards and in mitigating them should they occur. Project managers know all too well that the only way to ensure something happens is to ensure staff know that it is their job to do it, and know how.

Emergency plans should include:

- Identifying the hazards and who they would affect

- Assessing the risk of the hazard occurring

- Identifying who is responsible for controlling a hazard

- Instructions on how to control the hazard

Workers and other companies on site should be consulted in the creation of the emergency plan. Feel free to identify hazards with the help of the first section of this blog, the consultancy of your crane hire company, your workers, other companies on site, and your wet hire operator.

Hi-Range Crane Forks offers hi-rail crane wet hire

We supply telehandlers for hire with crane attachments, and with expert Hi-Range Crane Forks operators, across New South Wales. We pride ourselves on our skilled operators, expert consultancy, and attention to detail.

Contact us today for a free quote or crane hire advice, and our friendly team will get back to you as soon as we can.

Get a quote on rail track laying and more

Like what you see? Get in touch with our friendly team for more information on what services we can secure for your next rail construction project. Hi-Range Crane Forks can organise and assist with full-service rail construction packages and individual service contracts alike. From track clearing to installing continuous welded rail, our teams can provide assistance to commercial and civil projects of any size and scope across South Australia and New South Wales.